Welcome to L1 Supply Networks

Welcome to L1 Supply Networks

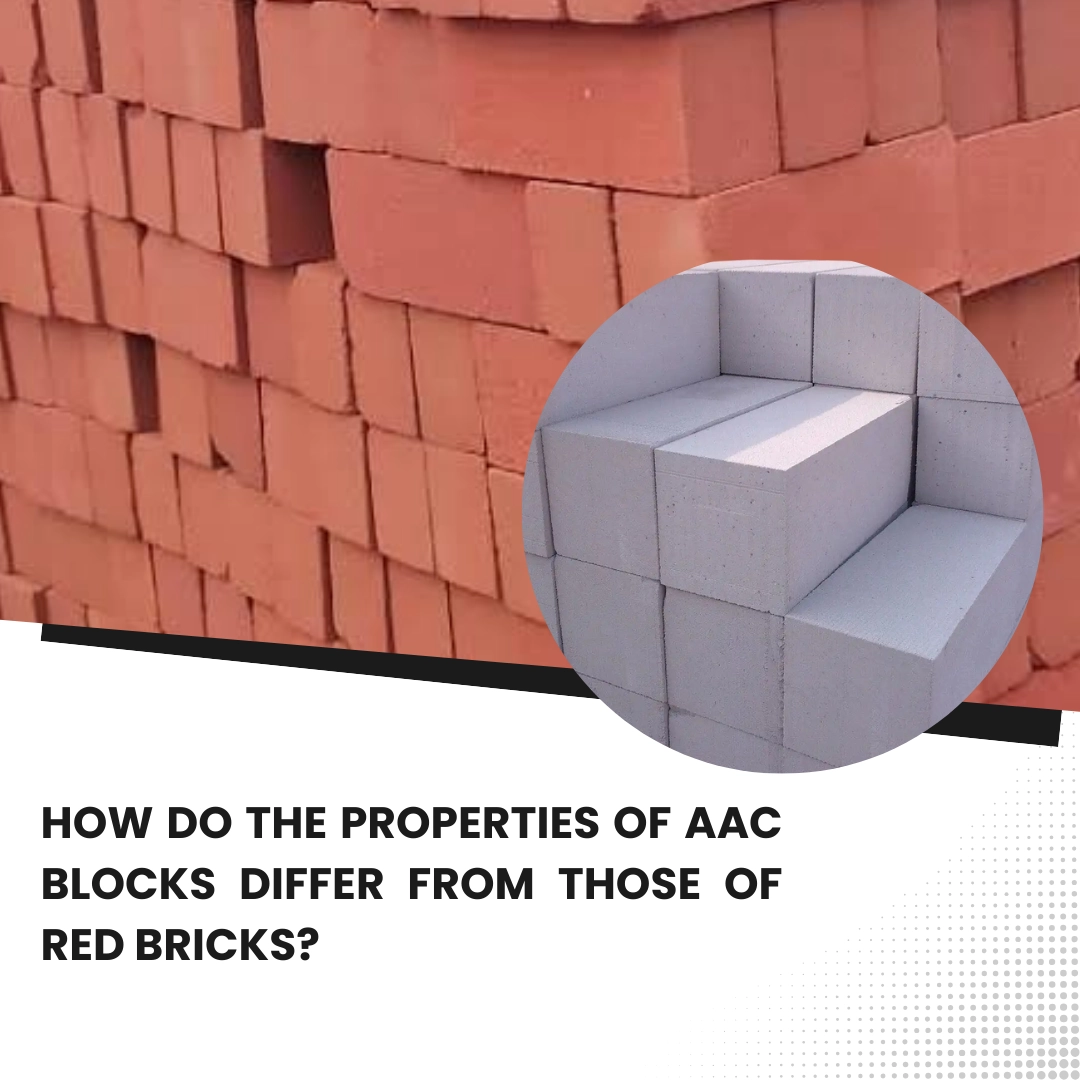

Red bricks - Red bricks have been used in construction for thousands of years and are composed of clay, water, and other aggregates. They are heavier than concrete bricks and are porous, allowing good heat insulation. density allows for longer durability, but they are more expensive than AAC blocks.

The solidification process comprises the thickening of the fresh or original cement paste, which is the plastic mass. An initial gel formation followed by crystallization keeps adding a definite level of hardness to the cement. As this process begins, it reflects that adequate strength is evolving because of the gradual and continued reaction between water and the particular cementitious component.

Water Cement Ratio measures how much water to cement is used in a concrete mixture. In simpler words, it's the relationship between the weight of water and cement in a mix. For structural strength, it's recommended to have a low water-cement ratio. According to IS code 10262, the recommended range for a nominal mix is 0.4 to 0.6. This ratio was discovered in 1918 by Abraham, who gave the following statement, “The strength of concrete is dependent on the net quantity of water used per sack of cement.”

Cement is the backbone of the construction industry, and choosing the right type can significantly impact the strength, durability, and eco-friendliness of your structure. In India, two of the most widely used types of cement are Ordinary Portland Cement (OPC) and Portland Pozzolana Cement (PPC). Let's dive into their properties and applications to help you make an informed decision.

The cement industry in India has a very high level of importance because of the ever-increasing need in the construction sector and the vast range of employment opportunities it provides. India is also currently the second-largest producer of cement in the world. It would not be surprising if the cement consumption of the country shoots up by around 55-65% within 5 years because of the high rate of usage for better infrastructure in the country. The following are the top 10 best cement brands in India, ranked based on total revenue earned by the companies and customer feedback: